Insulation Foam Blowing Agent

HFCs have been widely used as insulation foam blowing agents due to their technical performance, good insulation properties and low or non-flammability.

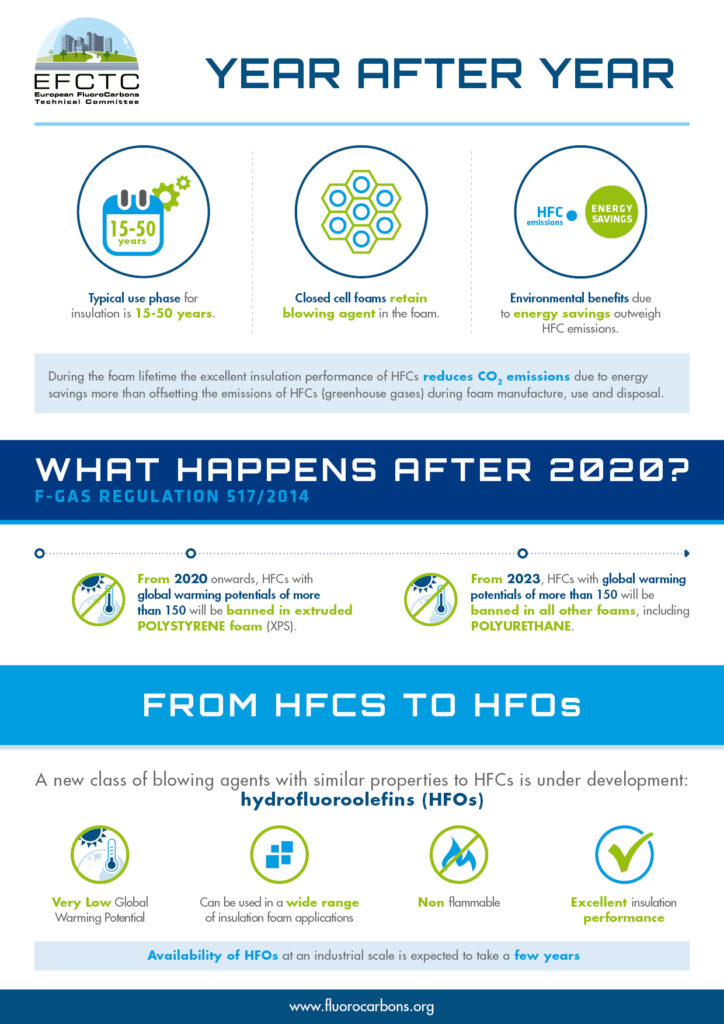

The very low GWP (≤ 7, IPCC AR5 values) non-flammable HFOs and HCFOs used as foam blowing agents provide a level of insulation performance which not only allows the replacement of blowing agents with high-GWPs, such as HFCs, but also has the potential to replace some elements of the hydrocarbon and CO2-blown sectors, based primarily on improved thermal properties.

The F-Gas Regulation 517/2014 bans the use of HFCs or HFC blends with a GWP >150 in the manufacture of all foams by 1 January 2023 and for extruded polystyrene (XPS) from 1 January 2020.

What makes a good insulation foam blowing agent?

The foam blowing agent is selected to provide a closed-cell structure which minimizes heat transfer, in part due to the properties of the foam blowing agent, which is retained within the foam essentially for the lifetime of the foam’s use.

Emissions of the foam blowing agent from closed cell foam are typically less than 2% per year, so that the thermal performance is maintained. The blowing agent used can be a liquid or a gas that is dissolved in the foam precursors and expands to form the foam once it is injected or sprayed and the foaming reaction begins. Optimization is crucial because thermal efficiency and overall performance is highly dependent on the formulation. The foam blowing agent and foam matrix, which may be bonded to impermeable metal facings, are selected to minimize migration of the blowing agent out of the foam which increases its thermal conductivity. Foam blowing agents with low thermal conductivity can improve the insulation properties of the foam, allowing either better insulation performance or thinner profiles for the same insulation value.

How do HFOs and HCFOs compare to hydrocarbons?

The very low GWPs (≤7, IPCC AR5 values) of HFOs and HCFOs mean that any blowing agent emissions that occur during foam blowing process, or for spray foam, during the use phase and at end of life have an extremely small impact on global warming. In fact, the GWPs of these HFOs and HCFOs are less than the main hydrocarbon foam blowing agent (pentanes, AR4 values, AR5 does not report GWPs for non-methane hydrocarbons).

Insulation properties for the HFOs and HCFOs are superior to cyclopentane, shown by their lower thermal conductivity and they are non-flammable. They are likely to be targeted mostly where the there is a requirement for improved thermal efficiency and, also where a non-flammable blowing agent is necessary.

Note: HFO-1234ze(E) (GWP <1) is also widely used for insulation foam

From TEAP Progress Report 2019 Volume 1, Flexible and Rigid Foams TOC (FTOC) Progress Report

HFOs/HCFOs ultra- low GWP, non-flammable high performance blowing agents

| HFO-1336mzz(Z) | HFO- 1336mzz(E) | HCFO-1233zd(E) | cyclopentane | ||

| GWP (AR5) | 2 | 7 | 1 | 11 | |

| Thermal conductivity λ (mW/m.K) | 10.7 | 11.5 | 10 | 13 | |

| Boiling point (°C) | 33 | 7.5 | 19 | 49 | |

| Flammability | no | no | no | yes | |

| Flash point (°C) | none | none | none | -40 |

Blowing Agent Blends

HFO/HCFOs are being blended together or with a range of other blowing agents to achieve the required balance of properties, performance and HFO/HCFO loading in final foam products. TEAP Progress Report 2019 Volume 1, Flexible and Rigid Foams TOC (FTOC) Progress Report gives examples of possible blends and their use for different types of foam.

The different foam insulation types and their uses

Polyurethane (PU), extruded polystyrene (XPS), expanded polystyrene (EPS) and phenolic foams contribute to reducing energy consumption in buildings, while XPS and PU rigid foams are the main foam types used within the cold chain.

The relative demand for each type of foam depends upon end-use, cost, availability and performance. XPS is preferred for insulating perimeters, facades, and flat roofs as it offers good mechanical properties such as high compressive strength and water-repellent surface texture. It is also used as a load-bearing insulation material in civil engineering due to its lightweight nature. EPS has many applications in construction and packaging; however, the oscillating prices of raw materials and stringent environmental regulations might hamper the global growth in demand. Conversely, the growing demand for recycled polystyrene products across the world is projected to provide new growth opportunities in the future.

From TEAP Progress Report 2019 Volume 1, Flexible and Rigid Foams TOC (FTOC) Progress Report

Extruded polystyrene (XPS) should not be confused with expanded polystyrene (EPS – also sometimes called ‘bead foam’) which uses pre-expanded beads of polystyrene containing pentane. EPS has never used fluorocarbon blowing agents.

Comparing insulation foam to other Insulation materials

There are a wide range of insulation such as fiberglass, rock wool, cellulose, and natural fibres, rigid foam boards and reflective foils. For many applications, insulation foams have advantages.

- The insulation performance is superior to a range of other insulation materials.

- The insulation and physical properties can be designed for specific applications.

- For a defined insulation performance, an insulation foam can be thinner, lighter and use less material than some other options.

- It can be formed in situ or used as prefabricated board stock.

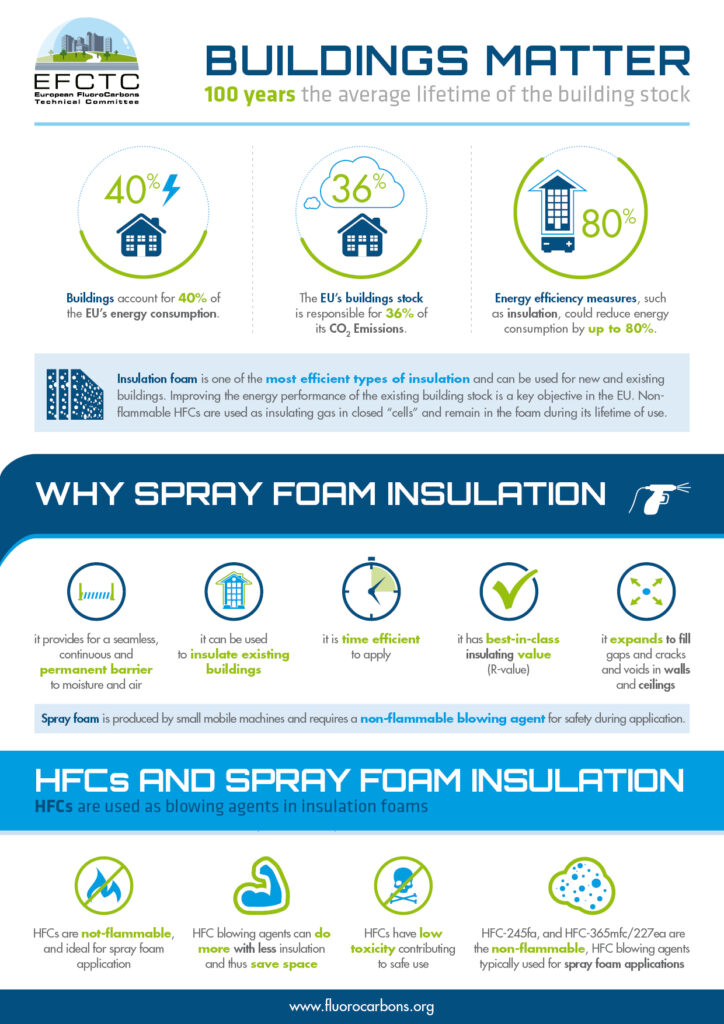

- Spray foam using non-flammable blowing agents can be used to insulate building stock or other structures as an efficient means of insulation which would be difficult to achieve in other ways, due to shape or location.

- It can provide a good water barrier. Extruded polystyrene (XPS) has a particular advantage in relation to its moisture resistance, which makes it especially useful for under-floor insulation and cold storage applications.

High performance insulation reduces energy consumption

High quality, high performance insulation improves energy efficiency primarily by reducing heat transfer. For building insulation, it reduces heat loss or heat gain which improves occupant comfort and can lower energy costs. For cold and chilled storage and transport, it reduces heat gain and helps maintain good temperature control.

The revised energy performance of buildings directive improves energy efficiency in buildings and encourages building renovation. Consistent with these energy performance issues, for both new construction and renovation, the demand for thermal insulation has increased substantially as the role of buildings in reducing energy dependency and greenhouse gas emissions has been recognised. Retrofitting insulation in the shells of existing buildings can significantly cut energy consumption.

Polyurethane Spray Foam

Non-flammable HFOs and HCFOs with low order of toxicity and very low GWPs (≤7) are particularly suitable for high insulation performance spray foam applications where flammable blowing agents are not acceptable.

Polyurethane spray foam has been used for many years as an efficient means of insulating structures which would be difficult to insulate in other ways, because of shape or location. An example would be that of an insulated road tanker. Another would be the insulation of large flat roofs, which may not be as flat as might be presumed! More recently, however, polyurethane spray foams have emerged as a vital component of renovation strategies for existing buildings. Again, the efficiency and versatility of application, as well as the relative durability and thermal efficiency are all characteristics, which have contributed to the rapid growth of PU spray foam in both developed and developing regions.” From UNEP 2014 Assessment Report of the Rigid and Flexible Technical Options Committee.