Heat Pumps

The safety and performance properties of HFC, HFC/HFO blends and HFO refrigerants make them suitable for use in heat-pumps, particularly where charge size and location exclude other options.

In 2019 “80% of heat pumps sold in 2019 contained R-410A refrigerants with R-134A being the second most common” according to BSRIA.

HFC-32 lower GWP HFO/HFC blends and HFO refrigerants are increasingly being used in heat pump applications.

How do heat pumps work:

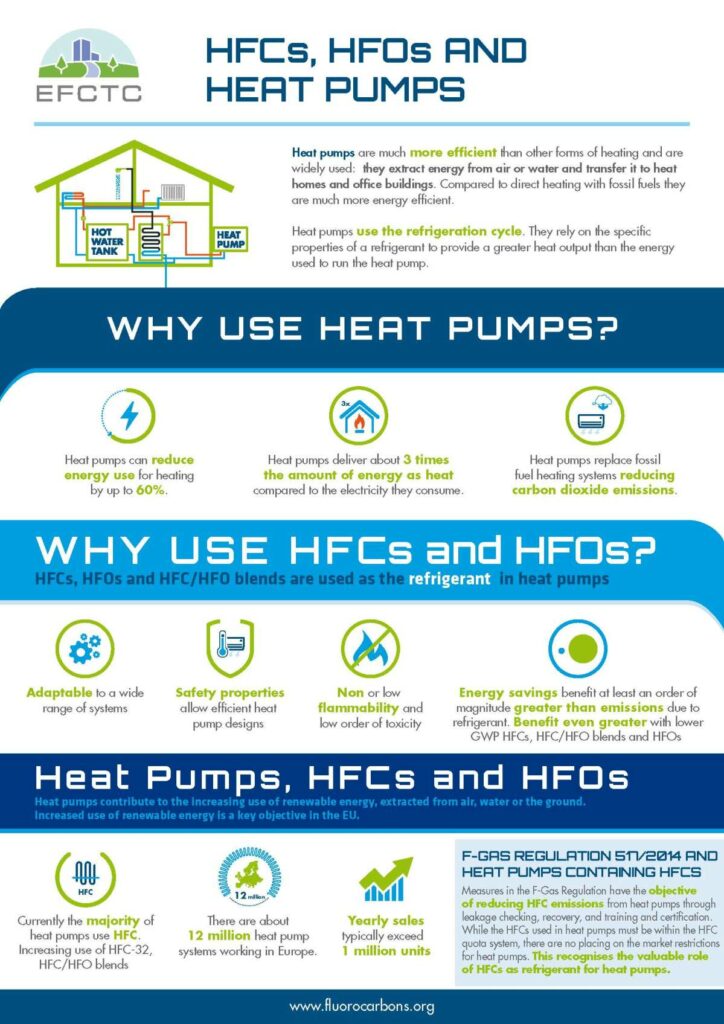

Heat pumps convert heat from a lower temperature to a useful higher temperature. The heat is used for space, water and manufacturing process heating. The low temperature heat source can be air, water, ground or low temperature waste-heat. Heat pumps use the refrigeration cycle and rely on the specific refrigerant properties including performance and safety.

How much energy can they save:

According to the European Heat Pump Association (EHPA), for each kW of electricity consumed by a heat pump, about 4kW of thermal energy is generated. This corresponds to a 300% efficiency whereas all direct heating methods are less than 100% efficient. Thanks to the 11.8 million units installed across Europe, heat pump technology has quickly developed into a cornerstone of Europe’s heat supply.

Heat pumps capture energy from renewable sources:

The amount of aerothermal, geothermal or hydrothermal energy captured by heat pumps is considered to be energy from renewable sources according to the Renewable energy sources directive (RED).

What about emissions of refrigerant from heat pumps:

Depending on the refrigerant used the level of benefit from using a heat pump is at least about an order of magnitude greater than the emissions associated with refrigerant loss. There are three main factors to consider for the emissions related to heat pumps.

F-Gas Regulation and Heat Pumps:

Regulation 517/2014 on Fluorinated Greenhouse Gases contains measures that apply to heat pumps containing HFCs. These are all the measures that have the objective of reducing emissions through leakage checking, recovery, and training and certification. While the HFCs used in heat pumps and, since 2017, for imported pre-charged heat pumps must be within the HFC quota system, there are no placing on the market restrictions for heat pumps (see also the stationary air-conditioning applications page). This recognises the valuable role of HFCs as refrigerant for heat pumps.

GWPs, classifications and applications for HFCs/HFOs/HCFOs and refrigerant blends subject to the F-gas Regulation can be found here

Heat pump applications use a range of lower GWP fluorocarbon refrigerants

Air- or water-to-water heat pumps use R-410A, but R-32 is replacing it in some systems, which is facilitated due to the water circuit transferring the heat. R-32 has higher efficiency than R-410A and a lower GWP (675 compared to 2088 for R-410A) contributing to lower over greenhouse gas emissions. R-454B (an A2L refrigerant with GWP 466) is also suitable as a replacement for R-410A in new systems designed for its s mildly flammable properties. R-407C is used for water- or ground- to water heat pumps and the mildly flammable HFC/HFO blend refrigerants R-454C or R-455A refrigerants with GWPs less than 150 have properties that may make then suitable as alternatives to R-407C but only in new equipment. R-134a is used for some small monobloc (hermetic) ground source heat pumps.

Heat pump (thermodynamic) water heaters for domestic or other hot water systems raise the temperature to higher temperatures (>60°C) compared to space heating requirements (25-40°C). Due to its non-flammability and properties, R-134a is used as refrigerant for some heat pump water heaters. HFO-1234ze(E) has suitable thermodynamic properties as an alternative to R-134a, but it classified as mildly flammable (2L). For combined space/water heaters R-32 is being implemented for some systems.

Heat pump tumble dryers are typically 40% to 50% more efficient than the most efficient condenser electric tumble dryers, contributing to reduced greenhouse gas emissions. Non-flammable R-134a and R-407C are used but The non-flammable HFC/HFO blend R-450A is being used as an alternative to R-134a as it has similar properties and a GWP of 605 (compared to 1430 for R-134a).

See air-conditioning section which includes reversible air-conditioners providing heating and cooling and the high temperature heat pumps section for industrial heat pumps

See also 2018 AFCE Final Report Energy Efficient State of the Art of Available Low-GWP Refrigerants and Systems. This report can be downloaded from the AFCE (Alliance Froid Climatisation Environnement) website.

Heat Pumps & Emissions

Depending on the refrigerant used the level of benefit from using a heat pump is at least about an order of magnitude greater than the emissions associated with refrigerant loss. There are three main factors to consider for the emissions related to heat pumps.

The comparison with direct heating: For each kW of electricity consumed by a heat pump, about 4kW of thermal energy is generated. This corresponds to a 300% efficiency whereas all direct heating methods are less than 100% efficient. The source of primary electricity generation and direct heating fuel will affect the relative emissions. Where nuclear or renewable primary sources are used to generate the grid electricity, then heat pumps have essentially no emissions associated with the electricity use.

The efficiency of the heat pump: If a refrigerant is used properly, the efficiency due to various refrigerants that are suitable for use at the applicable conditions, will typically have differences in the range +/-5%. For example, where appropriate for safety requirements, the switch from R-410A to R-32 improves energy efficiency typically in the range 5-10% and reduces refrigerant charge by about 15 to 30%. Heat pump design, including controls, compressors (eg inverter variable speed), heat exchangers, fans or water pump performance (for air to water heat pumps) and reducing heating loads can have a larger effect on energy consumption.

The direct emissions due to the refrigerant used: Refrigerant selection is based on energy efficiency, safety, reliability and technical performance, which is why non-flammable HFCs such as R-410A and R-134a continue to be widely used in heat pumps. Direct refrigerant emissions occur during the equipment lifetime (annual losses due to gradual leaks for non-hermetic systems), end-of-life disposal losses and failure losses (rare event). The consequences of refrigerant loss due to failure help determine the refrigerant safety classification required for the application. The refrigerant GWP will affect the benefit gained to a limited extent from using a heat pump assuming equivalent energy performance and the same refrigerant losses.

Illustration, comparison will depend on climatic conditions, emissions intensity for electricity generation and application. Assumes heat pumps with 4% annual emission rate, 15% end of life emissions and 15 years lifetime. Hermetic (monobloc) heat pumps have essentially no annual leakage except due to failures, but do have end of life emissions, reducing the contribution of refrigerant emissions to the total heat pump emissions.

For this example, HFC-410A contributes about 9% of the emissions due to the heat pump for the EU CO2 emissions intensity for electricity generation (but depending on climatic conditions and application). The switch to HFC-32 and A2L HFC/HFO refrigerants with similar GWPs reduces the refrigerant emissions contribution to about 3%. The use of R-454C with a GWP of 148 or similar HFC/HFO blends reduces the refrigerant contribution to about 0.7%. For larger heat pumps that may be used for district heating or industrial applications with compressors that can use lower pressure HFO refrigerants with a GWP <1 the contribution due to refrigerant emissions is insignificant (<0.005% at GWP=1). Reducing annual leak rates and end of life emissions will reduce these contributions further.

A report for the UK Department of Energy and Climate Change addresses the net benefit of heat pumps in the UK, taking into account the environmental costs associated with refrigerant leakage and came to similar conclusions The primary research and modelling indicated that whilst leakage led to significant CO2 emissions, this was nonetheless a small proportion of the total reduced emissions associated with heat pump technologies. It also highlights that there is scope to reduce leakage further, thereby increasing the net benefit associated with heat pumps.

References

- IIR 32nd Informatory Note on Refrigeration Technologies / October 2016 Harmonization of Life Cycle Climate Performance Methodology.

- RTOC 2018 Assessment Report Section 2.2.4 Refrigerants choice and energy efficiency.

- Overview of electricity production and use in Europe — European Environment Agency https://www.eea.europa.eu/data-and-maps/indicators/overview-of-the-electricity-production-2/assessment-4

Impacts of Leakage from Refrigerants in Heat Pumps

A report for the UK Department of Energy and Climate Change addresses the net benefit of heat pumps in the UK, taking into account the environmental costs associated with refrigerant leakage. The primary research and modelling indicated that whilst leakage led to significant CO2 emissions, this was nonetheless a small proportion of the total reduced emissions associated with heat pump technologies. It also highlights that there is scope to reduce leakage further, thereby increasing the net benefit associated with heat pumps.

Some of the key findings from the study are as follows:

It was determined from analysis of F-gas log books that annual leakage rates from operation of heat pumps were of the order of 3.8% of installation charge for non-domestic applications and 3.5% for domestic applications. However, these log books were generally of poor quality, leading to significant uncertainty within the modelling of this data.

Optimum charging has an impact on energy efficiency performance. Tests suggest that a refrigerant charge reduction of 10% would lead to a relative coefficient of performance (COP) reduction of about 3% in heating and 15% in cooling operation respectively. Undercharging the heat pump by 40% would reduce the relative COP by around 45% in heating mode and 24% in cooling operation. For the heating mode in particular this is a very significant reduction in performance.

The roll-out of heat pumps provides benefits in terms of their replacement of existing fossil fuel heating technologies. This benefit is determined by calculating the reduction in CO2 emissions compared to these counterfactual technologies. The results of this analysis show that for the UK the level of benefit is an order of magnitude greater than the emissions associated with refrigerant loss.

Impacts of Leakage from Refrigerants in Heat Pumps, Eunomia Research & Consulting Ltd and the Centre for Air Conditioning and Refrigeration Research (London Southbank University) March 2014