Life cycle refrigerant management report encourages better containment, following Europe’s lead

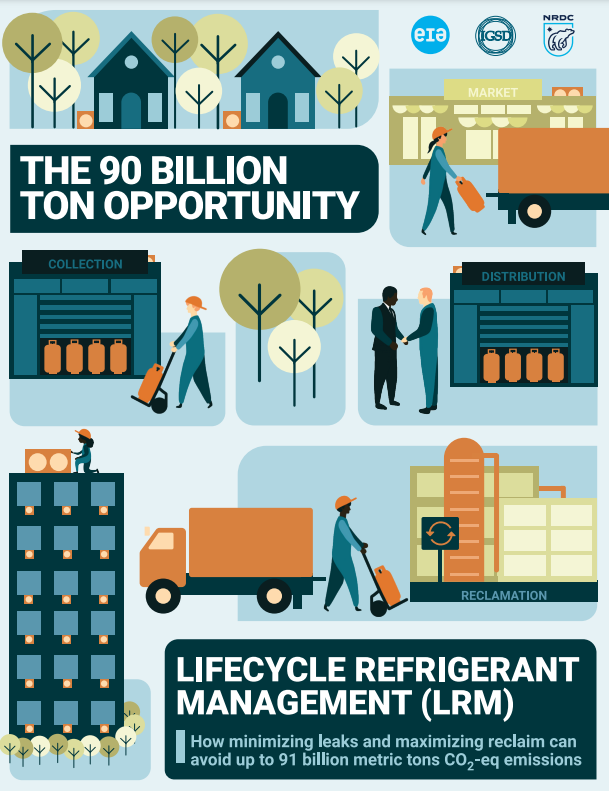

The report, “The 90 Billion Ton Opportunity: Lifecycle Refrigerant Management”, lays out how minimising leaks and maximising reclaim can avoid up to 91 billion metric tonnes CO2-eq emissions. Focussing on the USA the report states this significant opportunity for federal and state policymakers, major corporations, and equipment owners and operators. In the EU already reclaimed refrigerant is being used in new equipment, with reclaimed HFC-32 now being used in new chillers adding to the use of HFC-134a and R-410A in from screw and scroll compressor units to centrifugal compressor machines, but more needs to be done.

The report, “The 90 Billion Ton Opportunity: Lifecycle Refrigerant Management”, lays out how minimising leaks and maximising reclaim can avoid up to 91 billion metric tonnes CO2-eq emissions. Focussing on the USA the report states this significant opportunity for federal and state policymakers, major corporations, and equipment owners and operators. In the EU already reclaimed refrigerant is being used in new equipment, with reclaimed HFC-32 now being used in new chillers adding to the use of HFC-134a and R-410A in from screw and scroll compressor units to centrifugal compressor machines, but more needs to be done.

The life cycle refrigerant management (LRM) report identifies six pillars to the LRM approach (extracts):

Enhance product stewardship. Government or private entities can set up programs to help increase the responsibility of those higher up the supply chain, such as chemical producers and equipment manufacturers, to provide for economically and technically feasible LRM.

Increase refrigerant recovery, reclamation and reuse. At the end of an appliance’s life, the refrigerant should be recovered and sent to a company that cleans and resells it, a process called reclamation. Reclamation relies on refrigerant recovery for a steady supply of refrigerant so emphasis must be placed on making recovery of old refrigerant at end of life economical and enforceable.

Leak reduction. If they are not well maintained, cooling appliances leak refrigerant slowly but continuously. Targeting low leak rates is an extremely high priority for LRM because they can lead to large climate benefits at low cost.

Reporting and Enforcement. Stakeholders frequently report that a lack of enforcement aids and abets improper LRM practices in the field, including violations of existing law regarding refrigerant management.

Workforce development. A well-trained, specialized workforce is the bedrock of LRM. Technicians that handle refrigerants should be recertified by EPA based on the latest standards of practice, with ongoing learning and development opportunities to follow. [The F-gas Regulation has mandatory training requirements].

Installation and servicing. Installation is the starting point of HVACR equipment’s life, and LRM cannot be achieved without proper installation and verification. Servicing practices, such as the widespread technique of topping up leaky systems without repairing the underlying leaks, should be discouraged and avoided whenever possible.

In the EU, the use of reclaimed HFC-32 in new chillers R-32 has all the characteristics needed to be easily recovered, recycled, reclaimed to meet AHRI 700 standard (purity>99.5%), certified as equally good as the virgin refrigerant, and then reused. Under the F-gas regulation, only virgin refrigerants are part of the quota system, meaning that reclaimed refrigerants are not subject to the same constraints. This refrigerant reclaim programme is described a true example of circular economy of refrigerants, and environmental impact reduction. The reclaimed HFC-32 is reused mixed with virgin refrigerant as required for a wide range of products, from screw and scroll compressor units to centrifugal compressor machines.

Sources

The complete Life Cycle Refrigerant Management report “The 90 Billion Ton Opportunity: Lifecycle Refrigerant Management” and an executive summary can be downloaded from the NRDC website.

Use of reclaimed HFC-32 in the EU: Refrigeration Industry and manufacturer’s information.